Anyone who has used a sewing machine will be familiar with machine needles, but it’s surprising how much there is to know! I have learnt a lot about needles recently after updating our website, so I’d like to share some interesting and useful information with you. I’m going to focus on general information about needles for home sewing machines (overlockers and industrial machines take different needles), but I will go into detail about specific types of needles in a later blog post.

Reading the packet

If you buy a 5 or 10 pack of needles, it will come in a plastic storage case that gives you all the information about what sort of needles it contains. Domestic machine needles use the system 130/705, which you will see some form of on the pack, along with the code for the needle type. In the examples above, the Gold Jeans needles have the code 130/705 H-JT, the Microtex needles have 130/705 H-M and the Topstitch needles have 130 N. For clarity, the needle type is also written on the box, as is the needle size – if you can’t see it on the new Schmetz packaging then have a look at the top of the pack, it’s a little harder to spot up there!

Anatomy of a needle

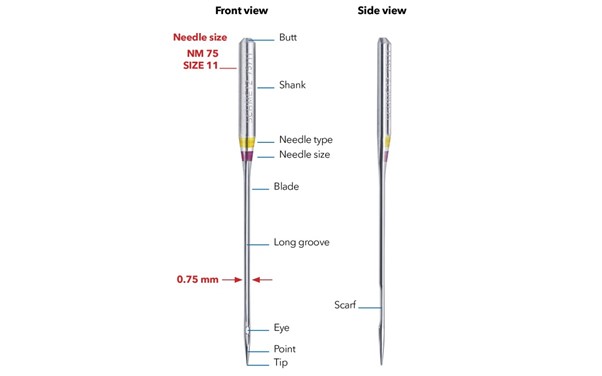

The thick end at the top of the needle, which you insert into the machine, is called the shank. The shank is flat on the back to help you insert your needle correctly, and you will find the brand and size of your needle stamped here. Below this you will see the colour markings that show the type and size of the needle, which I’ll explain in the next section. The blade is the main body of the needle, and it is the width of this that gives you the needle size: the thicker the blade, the larger the size and the heavier duty the needle.

The blade has a groove running down it, which the thread runs along until it gets to the eye, which is where the thread goes through the needle. The eye can come in different shapes and sizes – a Metallic needle has an elongated eye to reduce thread shredding and breakage, while a Quick Threading needle has a slit in the eye to one side to make threading easier. Turn your needle sideways and you will see the scarf – a cut-away section around the eye at the back of the needle. This allows your sewing machine’s hook to get as close as possible to grab the thread without hitting the needle. Never use very old sewing machine needles in a modern machine as they don’t have a scarf, so the hook can hit the needle and cause damage to both the needle and machine.

At the very end we have the point and tip of the needle, which also comes in different shapes and sizes. Needles with a ball point or a slightly rounded point push apart the fibres of your fabric rather than cutting through them, which can happen when a sharper point is used on jerseys, knits and stretch fabrics. A leather needle, on the other hand, can have a twisted or shovel point with the specific purpose of cutting through the material neatly, which is why you should never use a leather needle on woven or knit fabrics.

Colour coding to identify your needle

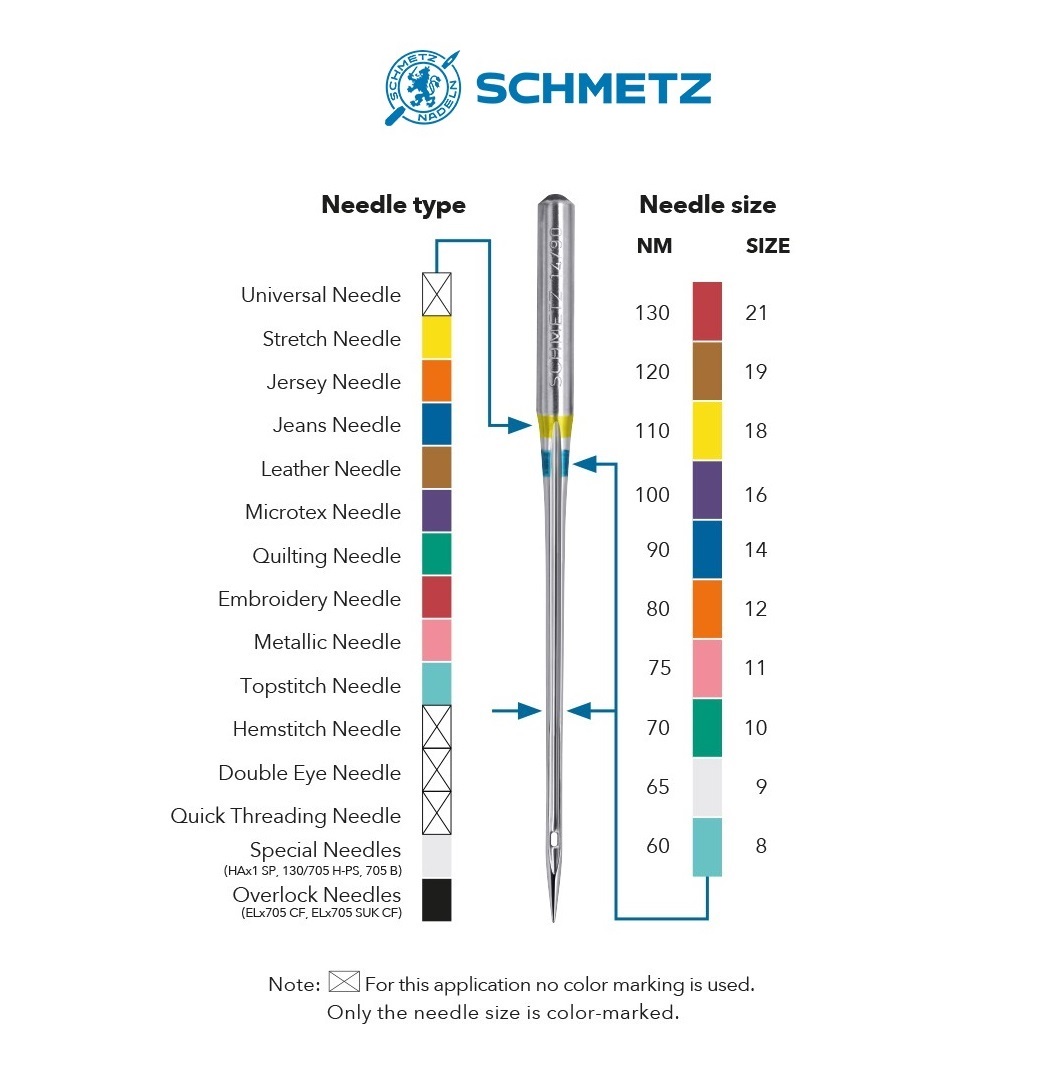

We’ve all done it – finished a project and tidied away the sewing machine with the needle still inserted. I’m sure it’s not just me that has had no idea what sort of needle it is next time I get my machine out. That’s where colour coding comes to the rescue! The most commonly-used needles have bands of colour at the base of the shank (the part that goes into the machine) so you can see at a glance what needle you’re using.

The top band tells you what type of needle it is and the bottom band gives the needle size. Make sure you know which brand you have (the name or logo should be stamped on the shank of the needle) as the conventions depend on the band. For Schmetz, a stretch needle in size 90 will have a yellow band on top and a blue band underneath, while a size 90 universal needle will have only the blue size band as universal needles don’t have a colour mark (any other needles without a top colour mark are easy to distinguish at a glance).

These colour bands are great because they are easier to see than the text on the shank if your eyesight isn’t great, plus you can see them even when the needle is inserted in the machine.

A note on coatings

Schmetz needles come with a chrome finish as standard, which helps to prolong the life of your needle. If you are doing some high intensity stitching or you are sewing something with an adhesive (like some embroidery stabilisers) then it’s worth taking a look at the needles that come with special coatings. Gold needles have wear protection and are great for heavy fabrics (e.g. Jeans needles) and sewing intensive projects (e.g. Embroidery needles); you can go for longer without needing to change your needle with a Gold needle. Black needles have a non-stick coating and are great for sensitive fabrics where you want the needle to slip in and out easily, as well as projects with self-adhesive elements, such as Stick & Sew Velcro, or anything with an adhesive stabiliser. The come in both Stretch and Universal.

Top tips

1. Change your needle regularly

It sounds like a way to sell more needles, but it really is important to change your needle regularly. Over time a needle develops wear and tear damage that you might not be able to see with the naked eye, but you might be able to tell from the behaviour of your sewing machine. Pulled threads in your fabric, skipped stitches, snapped threads and tangled bottom threads can all be caused by a dull needle, which is why we recommend that you use a new needle for every project, or every 6-8 hours of sewing. If your needle is visibly damaged then change it immediately – you can damage your sewing machine with a bent or damaged needle.

2. Use the right size needle for your fabric

You’d be surprised how many people use the same needle for everything! Yes, you can successfully sew something by always using the same size needle, but you will see a big difference in the quality of your sewing if you tailor your needle size to your fabric type. The thicker your fabric (and the more layers you are sewing through), the heavier duty your needle needs to be.

There are two numbers that denote the needle size and for both the larger the number, the thicker the needle. For instance, a 90/14 needle is thicker than a 75/11 needle. The first number is the most useful as this represents the thickness of the blade in hundredths of millimetres, so a 75 needle has a 0.75mm wide blade. The second number is the old style of needle size and is less commonly used these days.

We’ve put together a table to help you decide which needle size to use depending on your project, which you can find at the end of the post, but there are a couple of things that are particularly important to bear in mind. Firstly, if your needle is too thick for your fabric then you are likely to see holes where the needle has moved through your fabric – if this is the case then a smaller needle size is likely to help. Secondly, if your needle isn’t thick enough then you will struggle to get it to pierce your fabric, especially when sewing lots of layers. It’s easy to tell when your needle isn’t thick enough as it will bend or even break during sewing. This can damage your machine, so it’s best to be cautious and choose a thicker needle if you aren’t sure which size to choose – you can check by gently turning your handwheel to see that the needle moves easily through your fabric without deflecting or bending.

3. Use the right type of needle for your fabric/project

Okay, I’ll be honest. When I started working at Coles then I only ever used a Universal needle, but I had no idea what I was missing! Our needle table at the end covers the most commonly used needle types, so once again I’m going to mention the most important thing.

Universal really means “general purpose” rather than “can be used for absolutely everything”. Very often a Universal needle will do the job just fine, but there are times when more speciality needles will give a better finish, or even prevent problems. Jersey and stretch needles have a ball point, which can prevent the fibres of your knit, jersey or stretch fabric from being damaged. Microstitch needles, on the other hand, have a slim acute point that pierces densely woven or sensitive fabrics with ease and gives beautifully neat stitching when topstitching.

The wrong needle can damage your project, while the right needle can elevate it to a whole new level, so it really is worth planning your needle choice at the same time as choosing your pattern and fabric.

4. Insert your needle correctly

It seems like a ridiculously obvious thing to say, but make sure you insert your needle correctly. Loosen your needle screw until your old needle comes out easily. Hold your needle so the flat part of the shank faces the back of your machine and the needle is nice and straight. Push it up until it won’t go any further and hold it in place while you tighten your needle screw. Finger tighten, then give an extra 1/8th of a turn with your screwdriver, being careful not to over-tighten. Over-tightening can strip the threads on the needle screw and you’ll end up with your needles falling out. Give your needle a little tug to check you’ve tightened your screw sufficiently – if it doesn’t wobble or move then you’ve tightened it enough.

If this has given you the urge to try out some new needles then take a look at our Machine Needles department on our website – not only do we have a huge selection, but we also have 10% off Schmetz needles during January, so now is the perfect time to stock up!

I’d love to tell you more about all the different types of needles and why they’re worth having but that will have to wait for another day. In the meantime, the table below gives you an overview and there’s even more information on our website, or let me know in the comments if there’s anything you’d like to know more about!